General description

Flexible, modular, perfect in design, professional in handling!

Whatever you want to move, quake or transport. With the compact hydraulic units of the HF series from Hansa-Flex, every task can be optimally solved. The HF series is characterised by its flexible modularity and variance. Both the drive motor and the delivery volume, tank size and hydraulic functions can be flexibly configured.

The heart of the standard compact unit of the HF series is the aluminium centre adapter, weighing only approx. 1 kg, which can be used to fulfil various hydraulic circuit tasks or to which customised blocks with individual circuits can be flanged. In addition to a simple lifting and lowering function, numerous other functions are available. Both DC and AC motors can be configured and are flanged to the centre adapter to drive a size 1 gear pump with a wide range of displacement volumes. Plastic or steel tanks are available and both horizontal and vertical mounting positions can be provided. The units are suitable for stationary applications (e.g. heavy lifting tables) as well as for mobile applications (tipping trailers, attachments for winter equipment, pallet trucks, forklifts...).

You select the required configuration and Hansa-Flex delivers the unit ready for connection, fully assembled, adjusted and tested.

Function

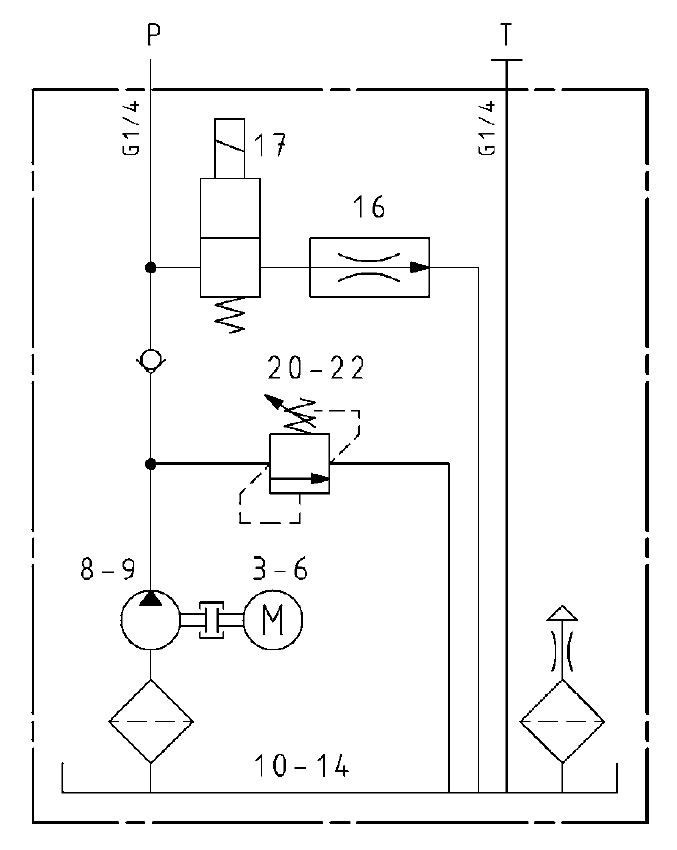

With the HF compact power pack series, simple lifting-lowering circuits can be realised. The hydraulic circuit diagram with the configurable options (see also configuration key below) is shown below.

The tank, pump size, motor type, pressure setting, directional valve and flow control valve are configurable items.

Details

The KH-power pack KHD037A08K050HFYB1A180 has got a 0,37 kW three phase motor (1450 U/min), 0,8 ccm/U displacement volume, 4,6 l/min flow and 250 bar max. pressure. It has an 5 liter plastic tank in horizontal mounting position, mounting foot, without flow control valve, 2//2-way poppet valve (NC) with 24 VDC selenoid. Motor mounting position is position 1, tank mounting position is position A. The seeting of the relief valve is 180 bar.

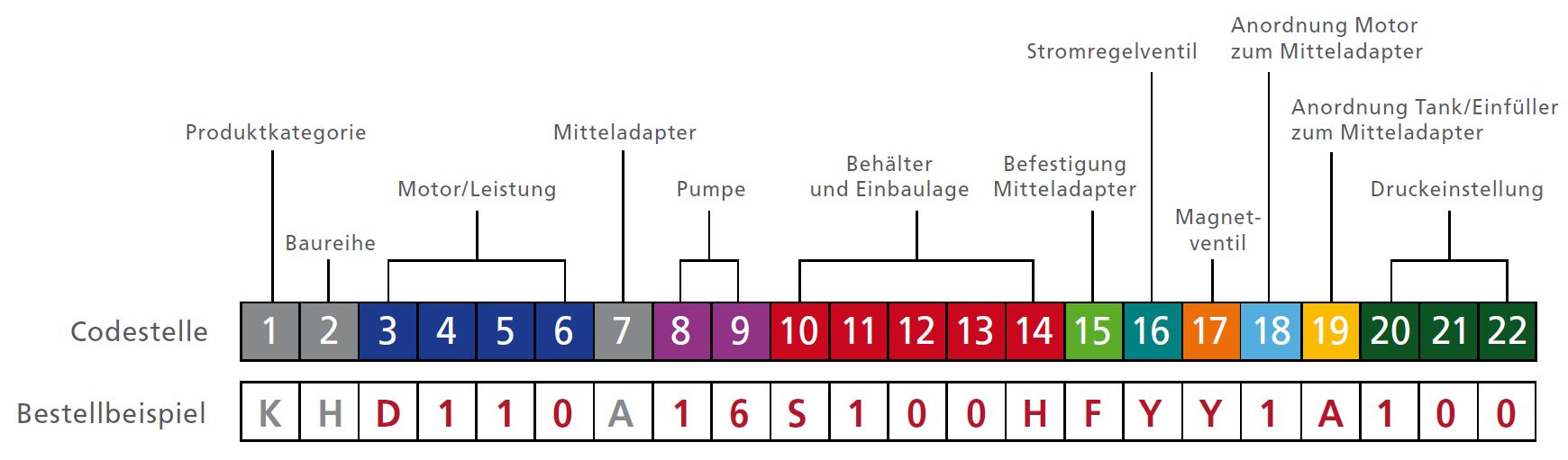

Configuration key

Subsequently the configuration key of the KH-power pack series is shown.

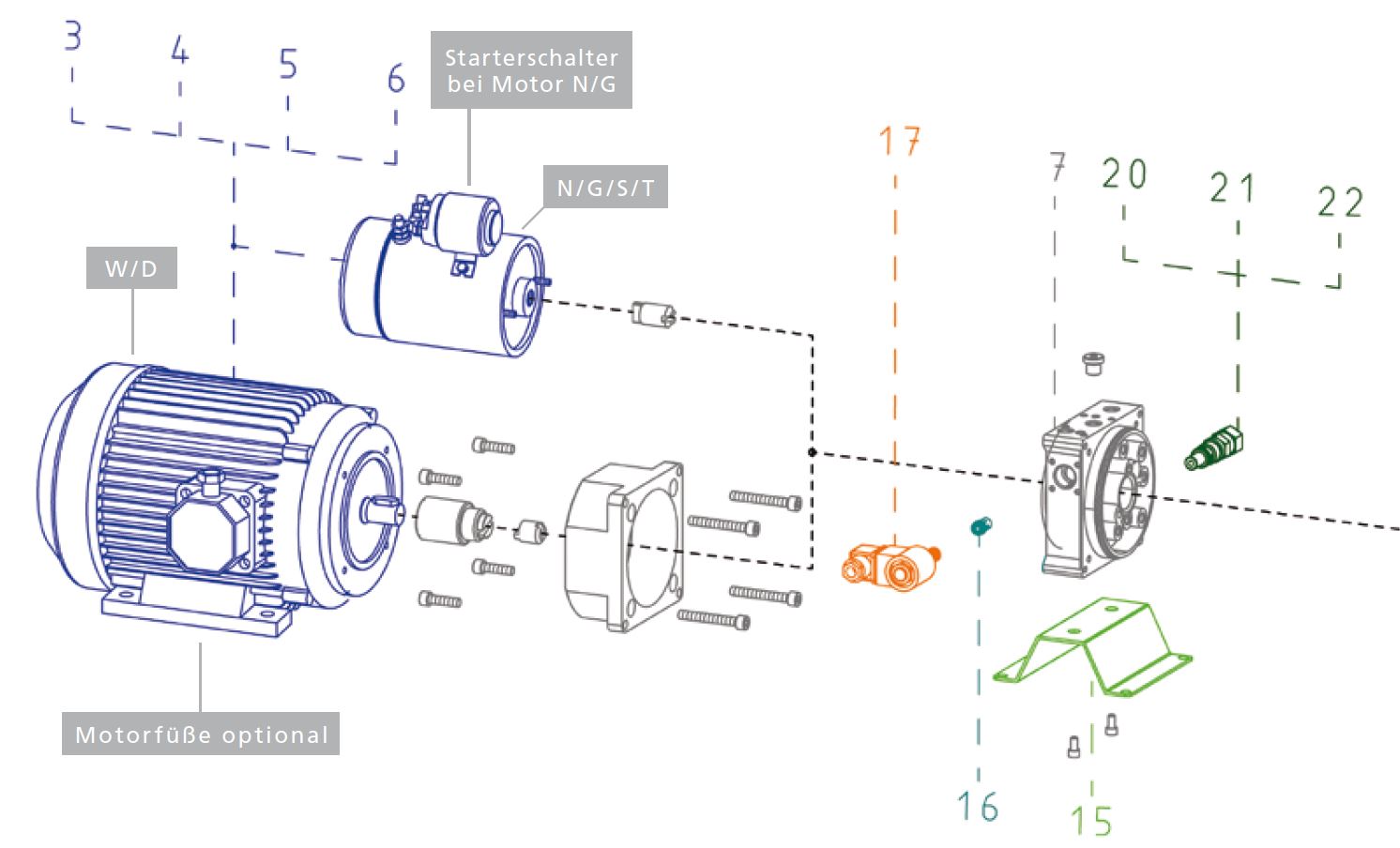

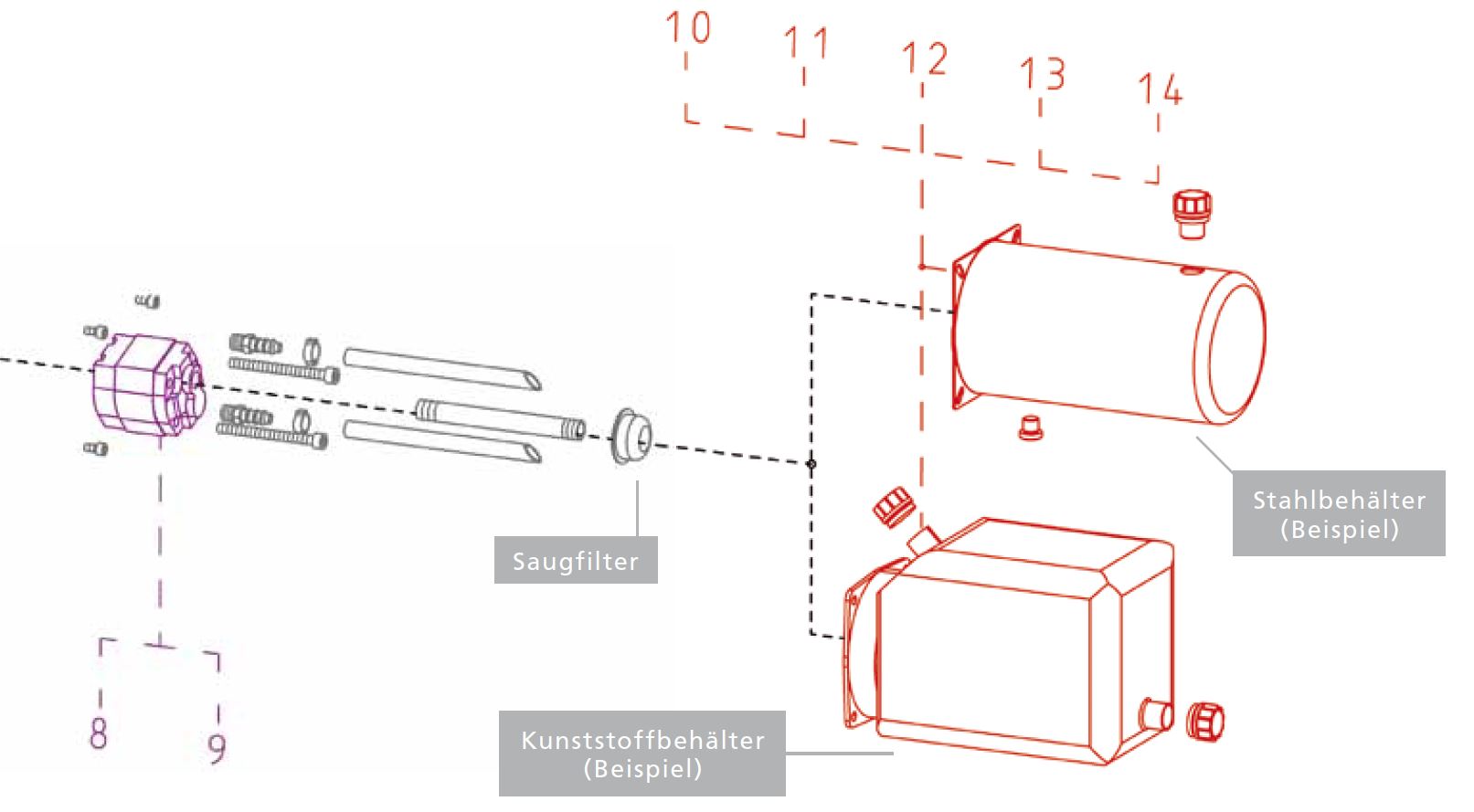

Each configuration digit determines individual attributes. Following all options are shown in an explosion drawing.

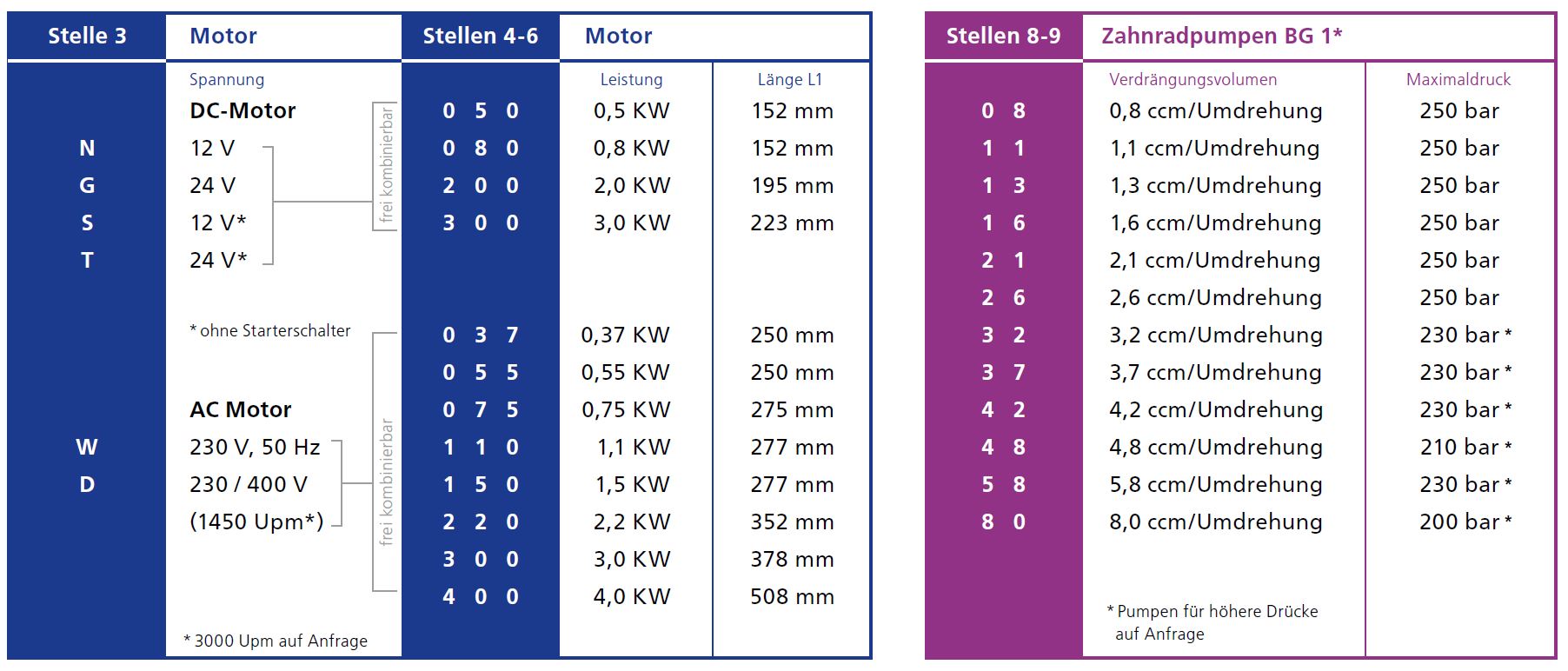

Digit 3 determines the supply voltage. Digit 4-6 configures the motor power and the motor length L1. Digit 8 and 9 define the displacement volume of the gear pump. Related to the pump size is the max. pressure.

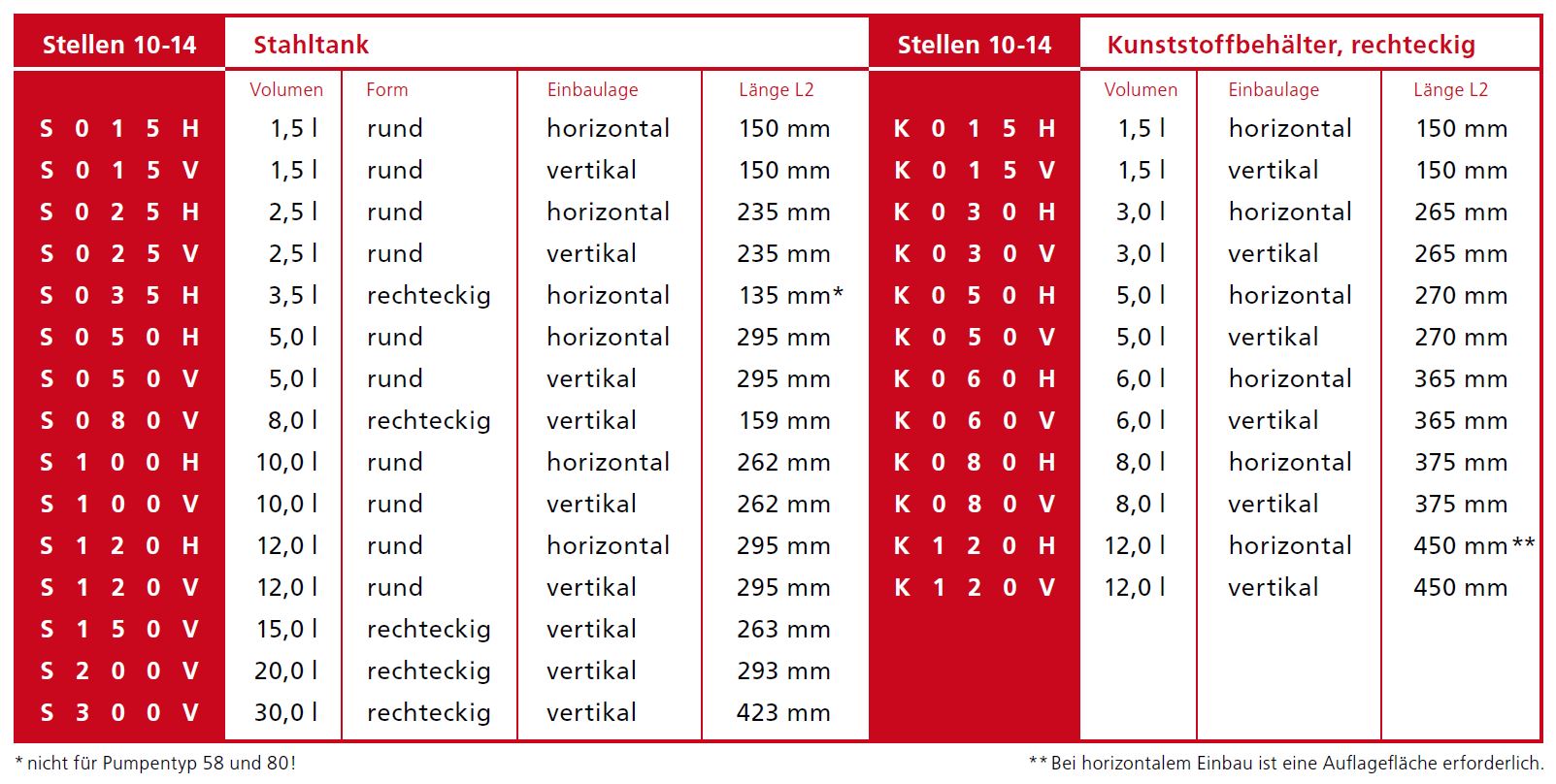

The digit 10-14 defines the tank type, the size of the reservoir as well as its shape, material, mounting position and length L2.

The shape and composition of the tank is shown in the following explosion drawing.

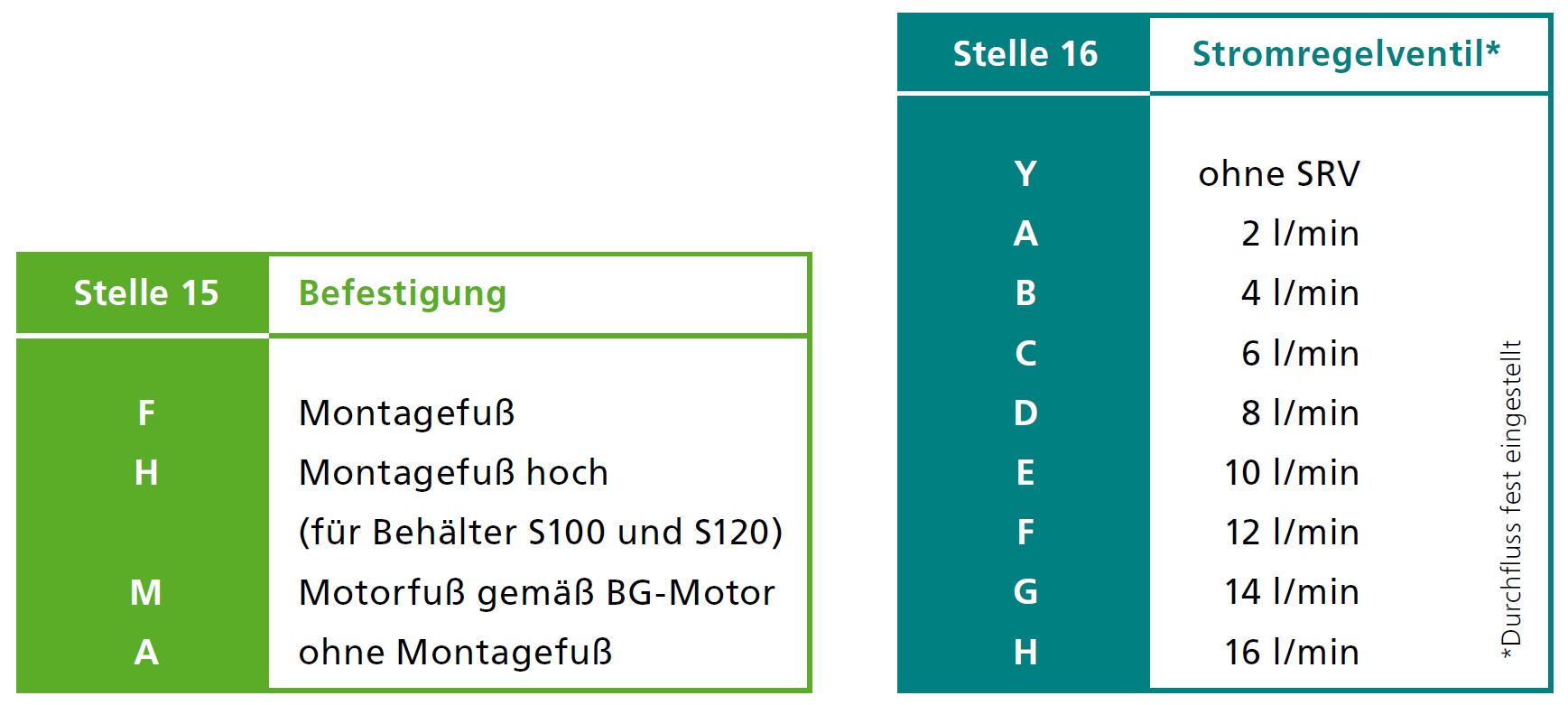

Digit 15 determines the mounting type and digit 16 the flow rate of the lowering flow control valve.

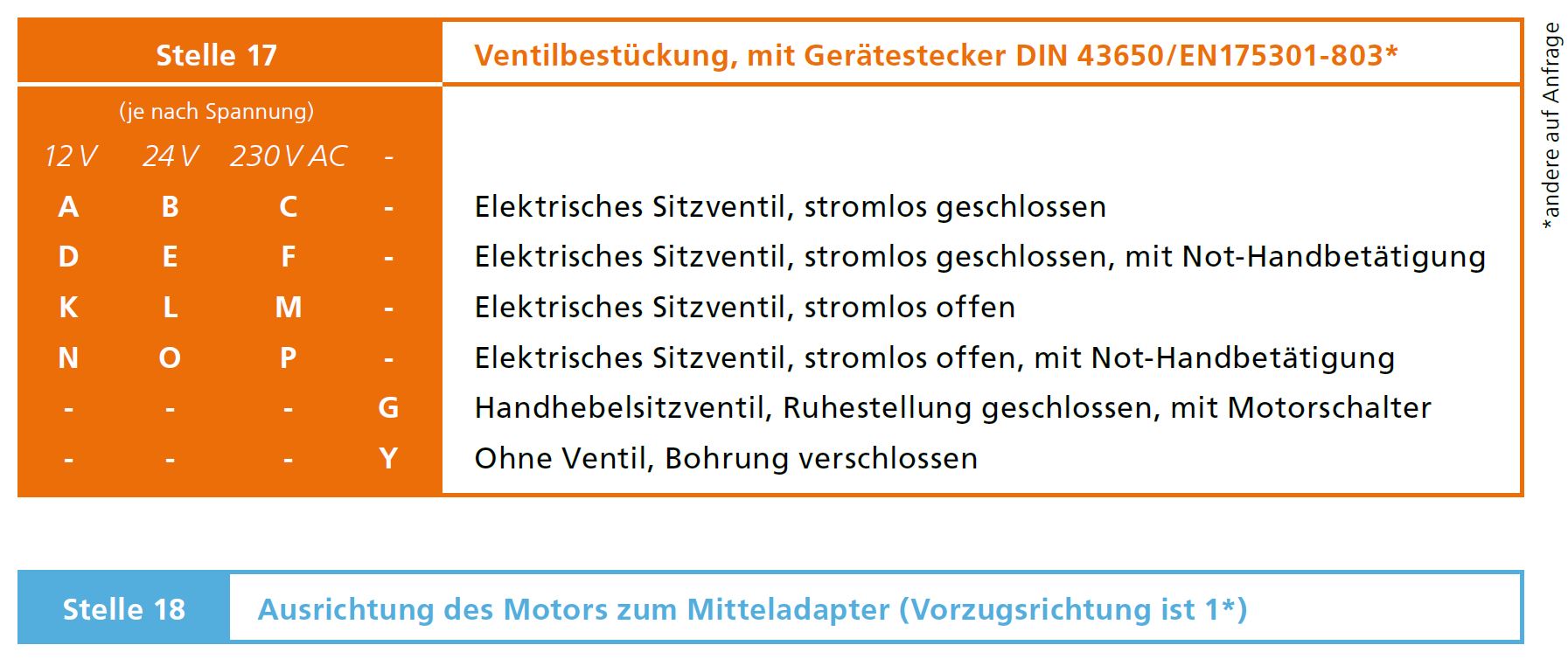

Digit 17 defines the attributes of the optional poppet type directional valve, e.g. manual operation, supply voltage (12VDC/24VDC/230VAC).

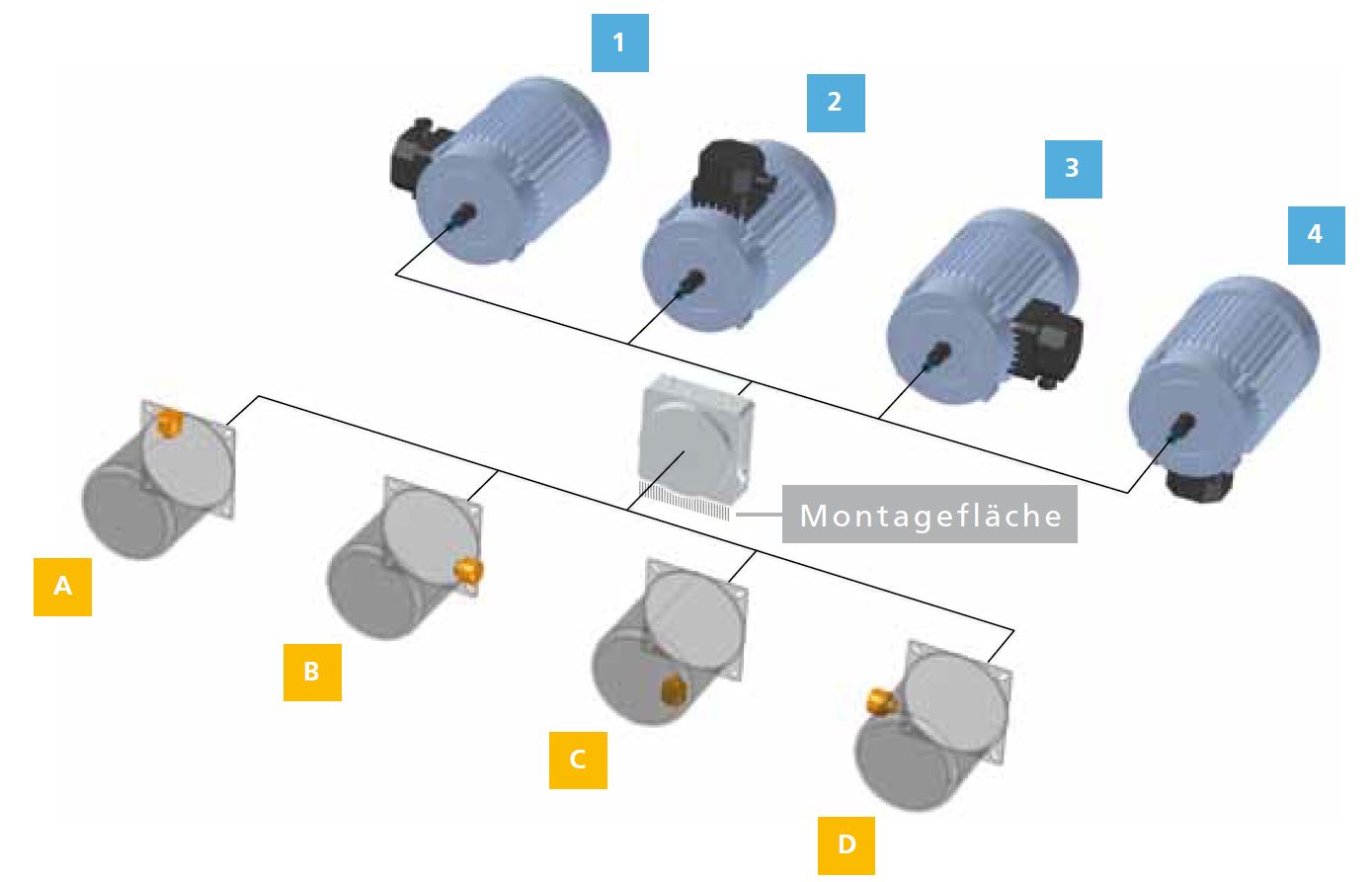

Digit 18 describes the orientation of the motor in relation to the center manifold, digit 19 the mounting position of the tank and breather. Available options are shown below.

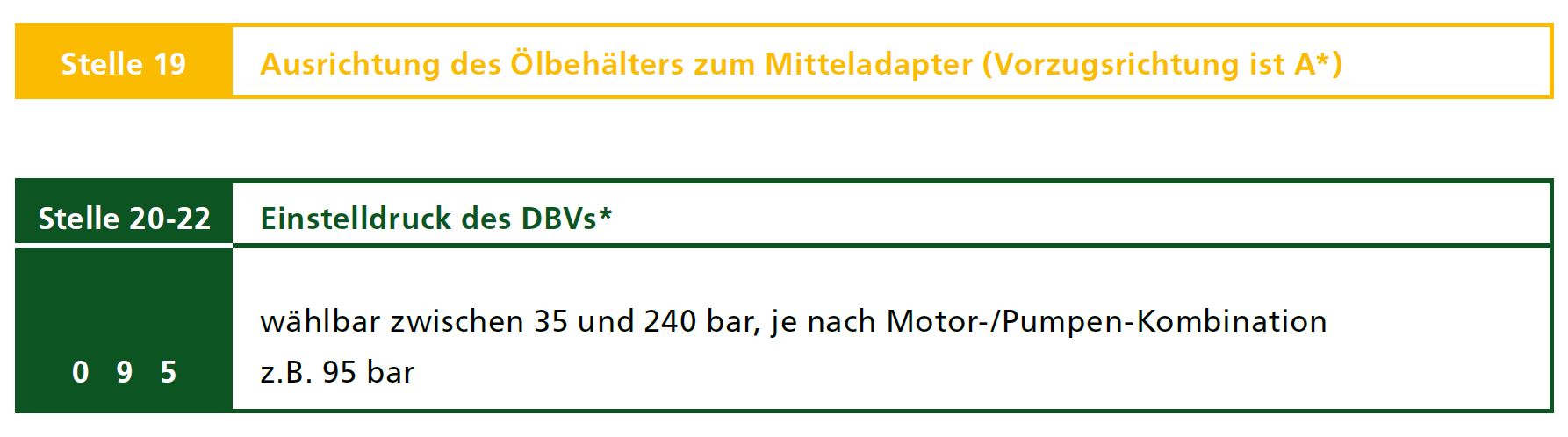

Digit 20-22 encode the pressure setting of the main relief valve.

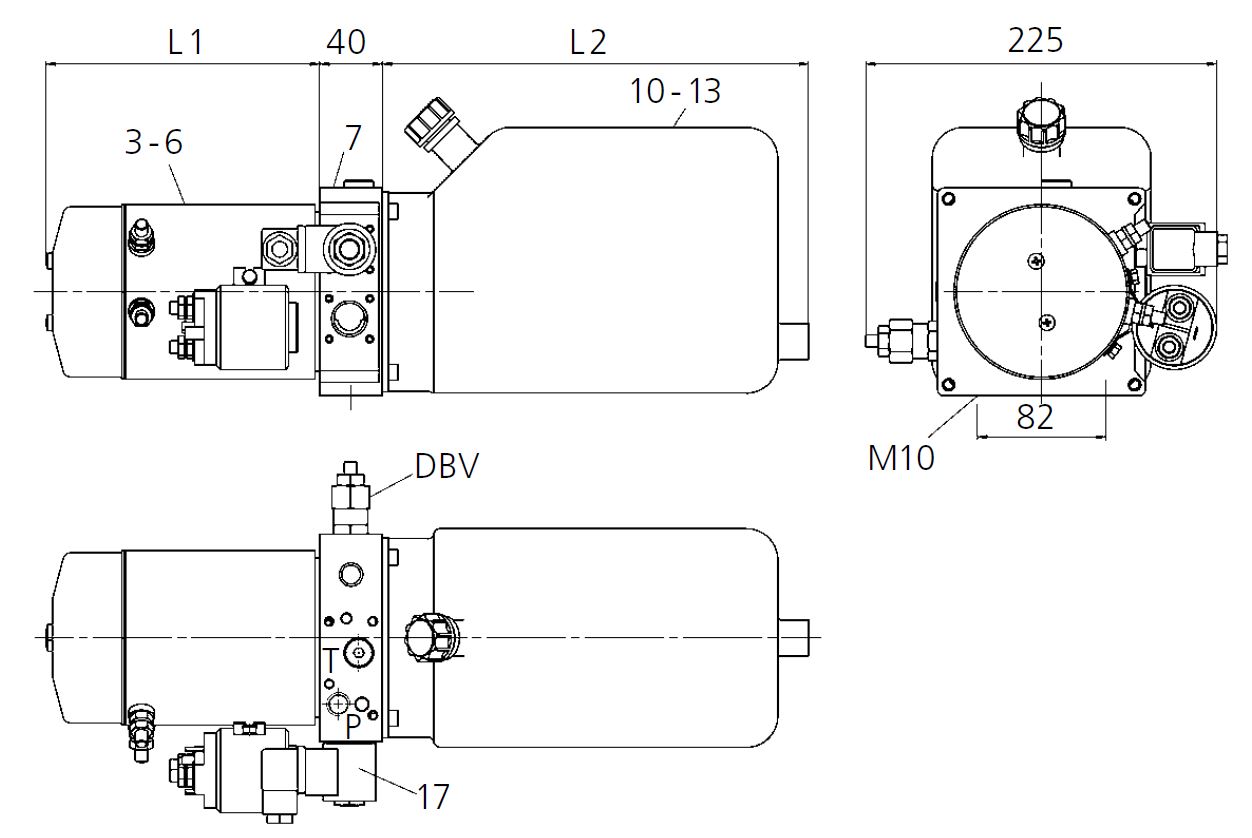

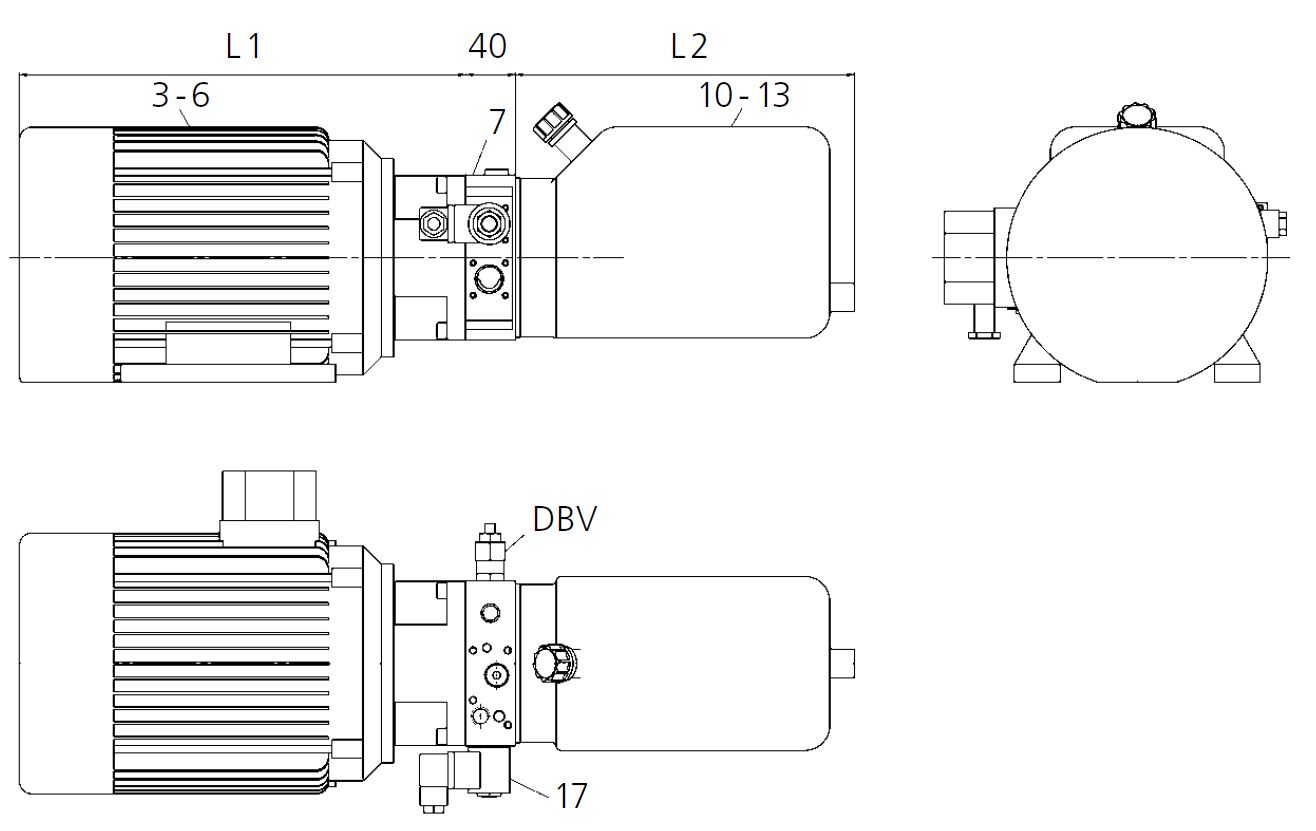

Dimensions

Subseqently the dimensions of the power pack are shown, for the plastic type tank configuration as well regate mit Kunststofftanks und Metalltanks, sowie Gleichstrommotoren und Wechselstrom/Drehstrommotoren gezeigt.

FLUITRONICS ist Spezialist für die Entwicklung und Fertigung kundenspezifischer Serienlösungen im Bereich der Antriebstechnik und Regelung. Sollten Sie keine passenden Produkte in unserer Datenbank finden, so sprechen Sie uns bitte an oder besuchen Sie unsere Homepage (www.fluitronics.com). Gerne zeigen wir Ihnen auf, wie der Weg zu Ihrer individuellen Lösung aussehen kann.